One size does not fit all: In the last 3 decades, supply chain has undergone an enormous change – from mass production to personalization. Companies like Amazon and Alibaba continue to evolve around the customer-centric model and offer buyers personalized and convenient digital marketplaces.

The focus has shifted to produce a product in any sizes, with different alternatives, and in the desired quantity. But this personalization approach adds more complexity to operations and open the door to emerging technologies like IoT, big data or robotic automation.

So does this means businesses just need to adopt the latest cool technologies to be successful?

In our 20+ years of SAP implementation experience, we’ve discovered that success depends on adopting the technologies that let you innovate and grow. Likewise, no two customer journeys are alike and their challenges are varied as well.

For instance, Fairfax Water and AstraZeneca both were underutilizing their SAP system and relied heavily on paper-based processes. Fairfax Water used paper notes to track time confirmation details whereas AstraZeneca used paper notes to track work order details.

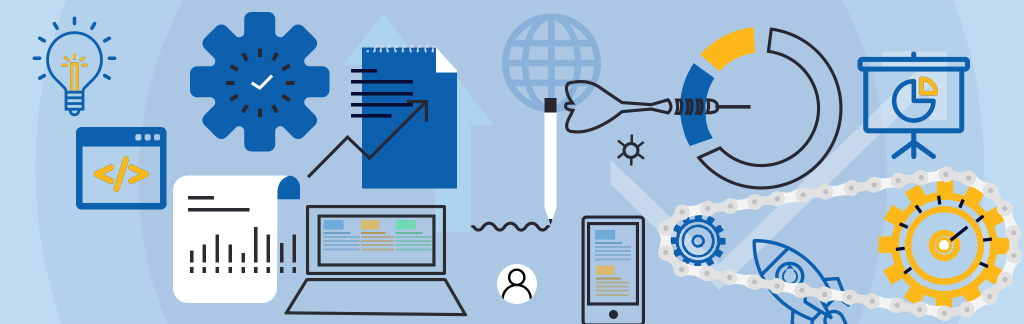

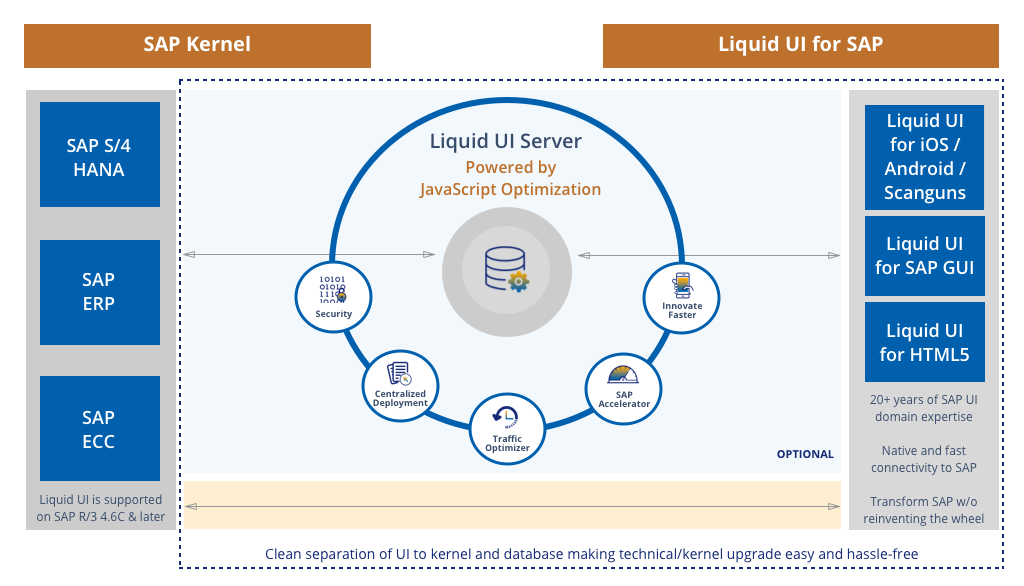

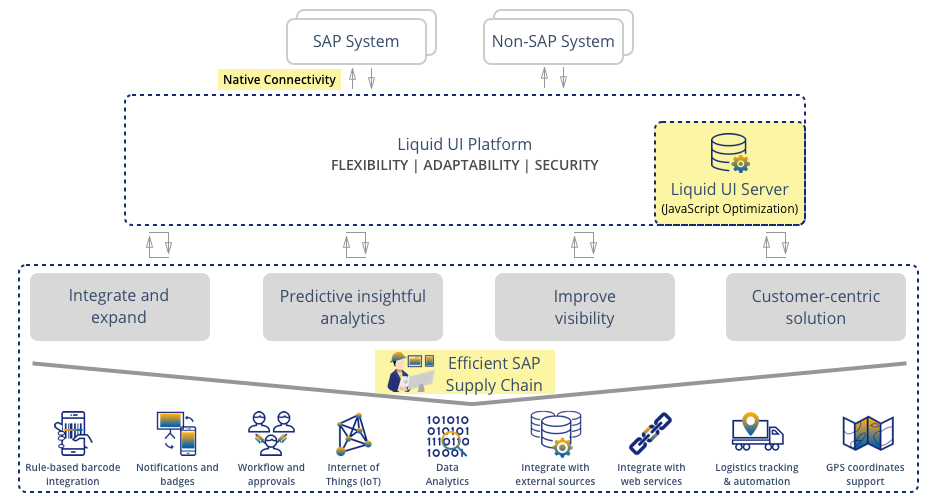

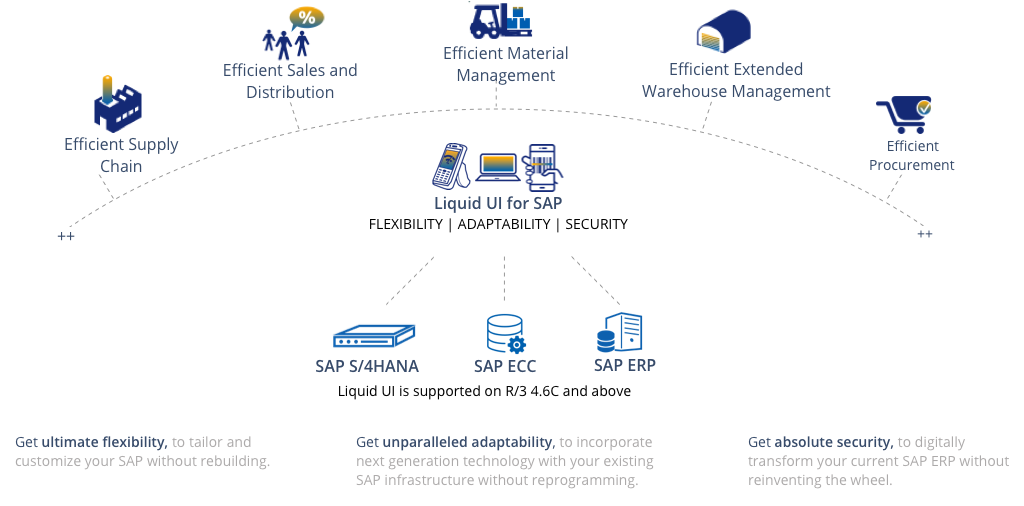

At Liquid UI, we understand the SAP Supply Chain/Asset Management and the uniqueness of each digital transformation. Our adaptive digital transformation approach makes SAP integration, SAP migration(from ECC/ERP to S/4HANA), and SAP customization hassle-free without any technology headaches.

HOW? Liquid UI provides a clean separation between the UI and kernel/database. We enable SAP customization with a single code-based JavaScript methodology across mobile, web, and desktop.

Consider it's like the intelligent wireless lighting system which can be used to maximize productivity at the office or create appropriate moods at home without having to experiment with multiple switches each time you desire a new effect.

Choosing the Right Approach

Depending on your challenges and type of business, one or a combination of the following approaches can help you move forward with your SAP digital transformation venture.

Integrate and expand

Thanks to technology, enterprises are revolutionizing their supply chain by moving toward automation and connected processes. From getting raw materials to producing personalized products to logistics operations, companies are embracing sensors, RFID, smart glasses, robotics cart, hands-free wearables and more.

- Improve order fulfillment with rule-based barcoding

- Get alerts about abnormal activities with notifications and badges

- Track goods movement with RFID

Liquid UI in Action: Graybar is using notification to alert their managers about blocked sales documents. The alerts contain all the required review information including the link to open a specific transaction in SAP right from their mobile device. Thus improving response time and overall operational efficiency.

Predictive insightful analytics

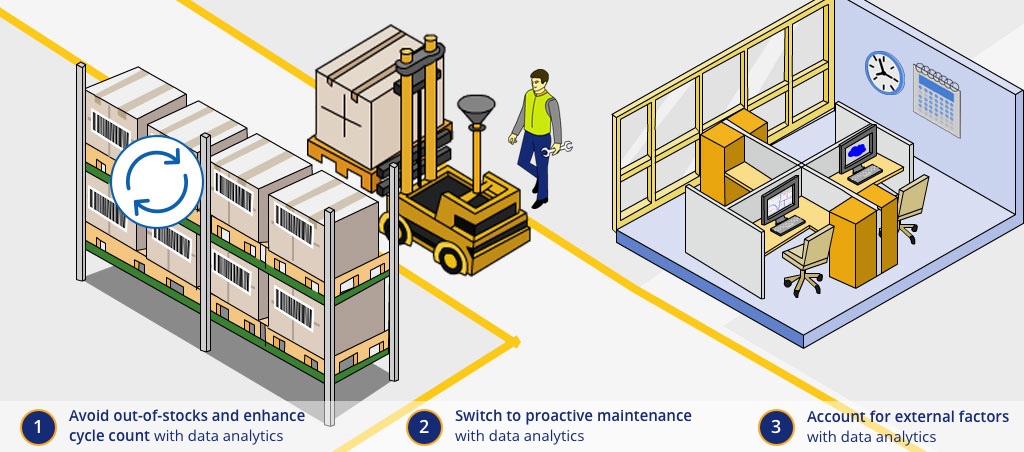

With the help of modern technologies like robotic process automation or digital twins, you can get insights into machine usage, goods movement, inventory management or space utilization. Such insights enable proactive maintenance, accounting external factors, avoid out-of-stocks, and maximize storage.

- Avoid out-of-stocks and enhance cycle count with data analytics

- Switch to proactive maintenance with data analytics

- Account for external factors with data analytics

Liquid UI in Action: Seattle Public Schools automated their entire employee's change of record process from 5 minutes to 30 seconds resulting in a 90% increase in productivity. A major Sports Goods Manufacturer automated their entire order handling process to get accurate estimates on pending orders, inventory requirements, pallet quantities w.r.t. cartons, and warehouse storage requirements.

Improve visibility

When it comes to optimizing supply chain performance, without real-time visibility best guesses aren’t enough. IoT data combined with robotic learning can enable inventory usage, goods movement insights, logistics status, external factors effects and more.

- Access real-time data with out-of-the-box comprehensive mobile apps

- Learn usage details with robotic learning combined with IoT data

- Get complete data visibility through integration with external data sources

Liquid UI in Action: Procter and Gamble integrated their external database(which is used for processing return merchandise from Walmart) into SAP. Now, the users can view and edit external database information right within SAP. Thus eliminating any back and forth or manual copying and pasting of data. Tata Power reduces their collection cost by 162% by automating and mobilizing their SAP-based billing system using Liquid UI for Android, as-is.

Customer-centric solution

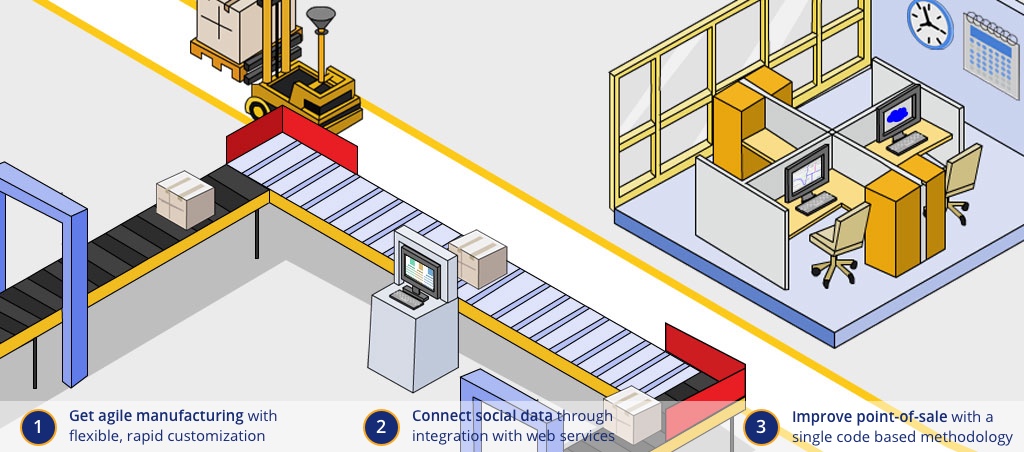

In a digital economy, a customer-centric model is more than just aspiration. Its created by sensing both long-term and short-term demand through orders, point-of-sale, IoT and social data along with agile manufacturing processes.

- Get agile manufacturing with flexible, rapid customization

- Connect social data through integration with web services

- Improve point-of-sale with a single code based methodology across mobile, web, and desktop

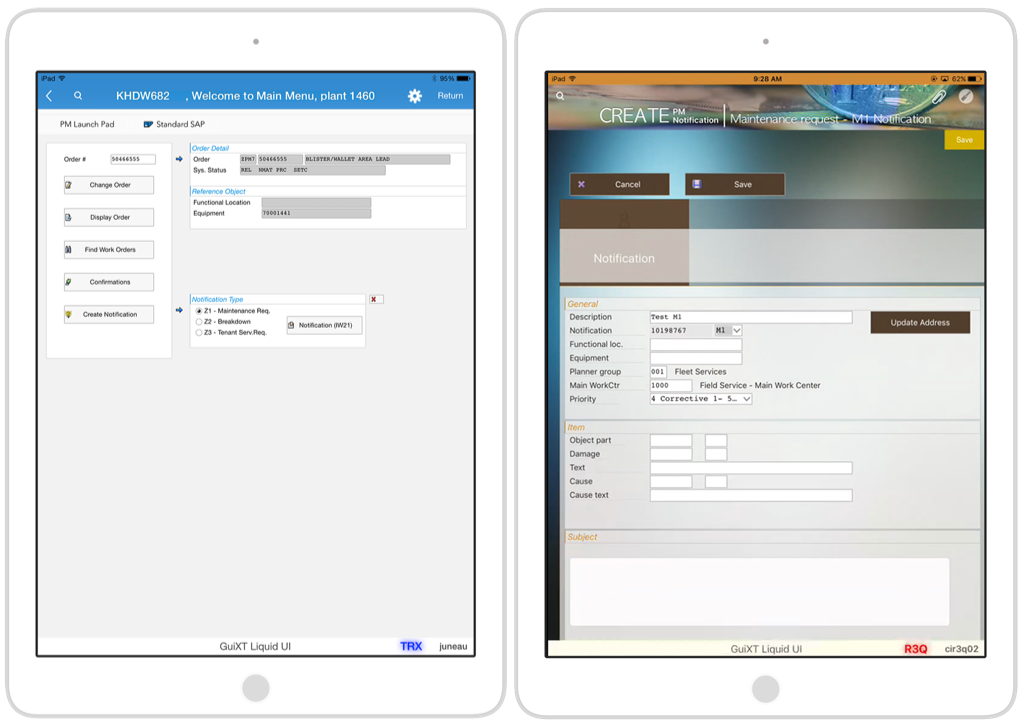

Liquid UI in Action: AstraZeneca cuts their processing time by 50% by streamlining their SAP PM initially on desktop systems and later extended the same solution on mobile devices. Similarly, Fairfax Water improved their revenue and data integrity by customizing their SAP PM initially on desktop systems and later extended the same solution to mobile devices.

Take the next step

Explore how Liquid UI can help your SAP infrastructure to incorporate next-generation technology along with rapid customization while reducing cost, overall workload, and environmental waste.

QUESTIONS? Visit us at liquid-ui.com to learn more or Call Us at 1-650-341-3310 to talk about our next-gen customization technology for SAP, including mobility without reprogramming.

FEATURED EBOOK

Post written by Punil Shah, Director of Digital Marketing